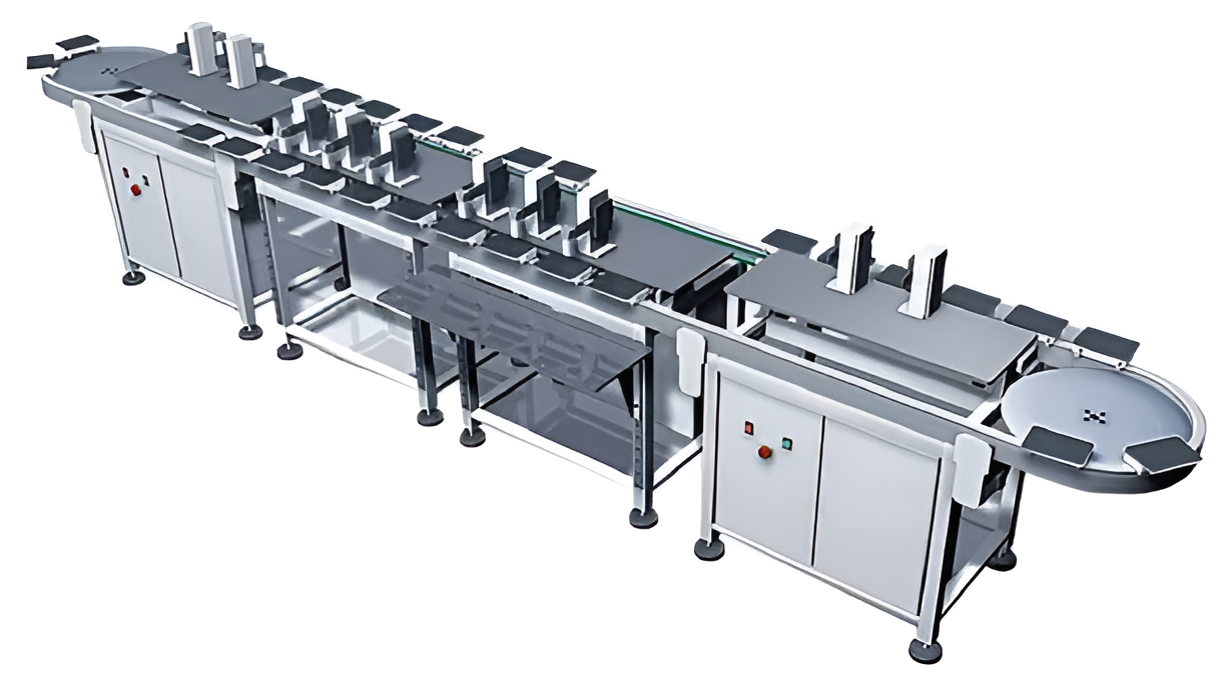

Rotary Linear Indexing Systems are advanced automation mechanisms used to precisely move parts between workstations in manufacturing and assembly lines. These systems combine rotary and linear motion to provide flexible, high-speed, and accurate positioning. The rotary indexing table allows for circular movement between multiple stations, while the linear axis moves components in straight paths, enabling complex and multi-directional part transfers. This hybrid system is ideal for compact workspaces and supports operations such as machining, inspection, assembly, and packaging.

Equipped with servo motors or pneumatic drives, these systems offer precise control, repeatability, and integration with robotic arms or sensors. They are commonly used in industries like automotive, electronics, medical devices, and consumer goods where consistent part orientation and reduced cycle time are critical. The indexing process ensures that each part stops at the exact location needed for the next operation, improving throughput and minimizing error, making it a key component in modern automated production lines.

Intermediate Storage : Temporarily stores parts/products between processes to balance workflow and prevent bottlenecks.

Process Decoupling : Allows upstream and downstream machines to operate independently, improving line efficiency.

Space Optimization : Utilizes vertical space efficiently, reducing floor space requirements.

Automated Loading & Unloading : Integrates with robots or conveyors for seamless material handling.

Increased Line Flexibility : Absorbs variations in cycle times or downtimes between different workstations.

Inventory Control & Traceability : Monitors part count and movement for better control and data logging.

Improved Production Continuity : Reduces machine idling or stoppages, maintaining consistent flow.