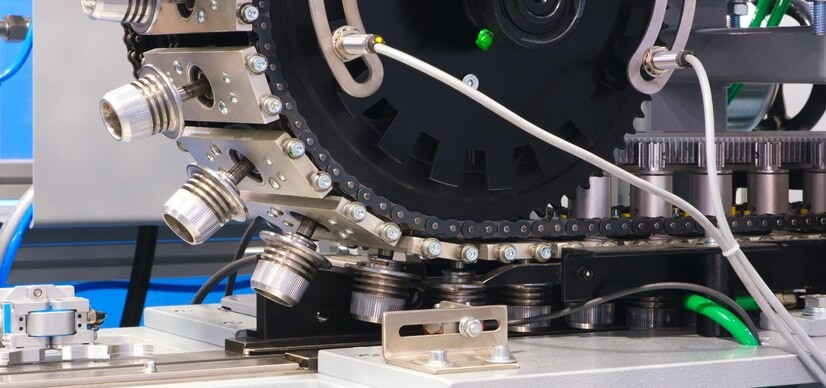

Cam driven machines use specially shaped cams to convert rotary motion into precise linear or reciprocating motion, enabling automated mechanical operations. These machines are widely used in manufacturing processes for tasks like indexing, pressing, forming, stamping, and packaging. The cam profile determines the exact motion and timing of the follower or tooling components, ensuring high-speed and repeatable accuracy. Cam-driven mechanisms are ideal for synchronized multi-station operations and are commonly found in automotive, pharmaceutical, and packaging industries. They offer advantages such as low maintenance, mechanical reliability, and fast cycle times without the need for complex electronics. With predefined motion paths, cam driven machines are excellent for high-volume, precision-oriented production. Common types include plate cams, barrel cams, and cylindrical cams, each designed for specific movement patterns. Their mechanical simplicity ensures durability and consistent performance in demanding industrial environments.

Precise Motion Control : Converts rotary motion into complex linear or oscillating motions with high accuracy.

Synchronization of Multiple Operations : Ensures multiple machine elements operate in perfect timing—ideal for automated assembly lines.

Repeatable and Reliable Movements : Offers consistent mechanical motion, critical for high-volume production environments.

Customizable Motion Profiles : The cam profile can be designed to control the speed, dwell time, and stroke of components.

Compact Design : Enables complex motions in a small mechanical setup, reducing space requirements.

Low Maintenance Operation : Fewer electronic components mean less maintenance compared to servo-driven systems.